Products

Gerdau Summit S.A – Villares Rolls BRAZIL

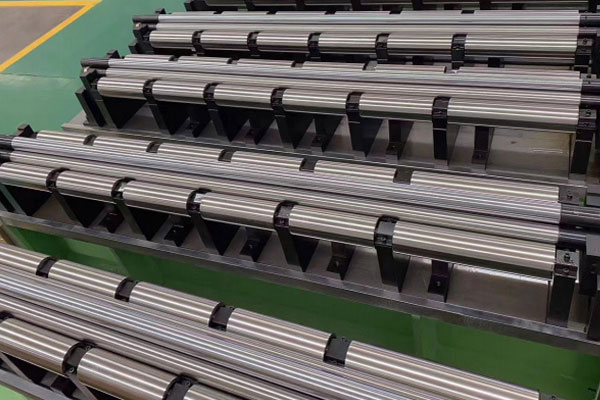

Rolling Mill Rolls

- High Quality Rolling Mill Rolls

- Cast and Forged. Work Roll, IMR and BUR

- For Cold Rolling Mill, Hot Rolling Mill

- Flat Products and Long Product Industries.

Back up Rolls

Rolls are manufactured from degassed steel by means of a vacuum process that presents a high level of purity. Forging occurs in hydraulic presses to guarantee high toughness. They are used in continuous hot-strip, steckel-type and cold strip mills, withstanding the most severe rolling conditions. Product development guarantees a performance which is far superior to that of cast back-up rolls. The microstructural homogeneity of these products allows for applications involving high hardness ranges and high resistance.

Rolls for Cold Roll Application

These are manufactured from degassed steel by means of a vacuum process that presents a high level of purity. Forging occurs in hydraulic presses to guarantee high toughness. Heat treatment is carried out by a double-stage progressive induction process.

Rolls for Hot Strip Application

Manufactured in an induction furnace, rolls are cast by centrifugation, which results in excellent structural homogeneity. They are used in the initial and final finishing stands, containing a high-strength gray cast iron or nodular cast iron core, which meets current flexion and displacement requirements of high-productivity rolling mills. Centrifuged cast rolls for finishing stands in hot strip mills are manufactured according to the most modern technologies available today.

TAIER HEAVY INDUSTRIES – CHINA

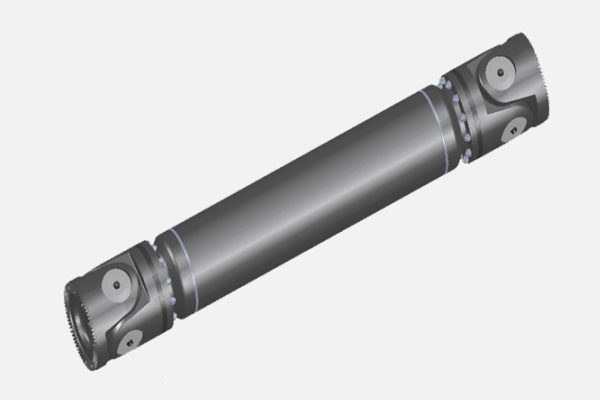

High-speed Cold Rolling Cross-axle Universal shaft

Technical Parameters Of Product:

- Operating temperature:-20~+80℃

- Torque range:130kNm~1150kNm

- Swing diameter:285~550mm

- Installation angle:±5°

- Maintenance cycle: 360h/time

Heavy-duty Cross-axle Universal Shaft

Technical Parameters Of Product:

- Operating temperature: -20~+80℃

- Torque range: 1700kNm~19405kNm

- Swing diameter: 600~1300mm

- Maximum angle: ±10°

- Maintenance cycle: 360h/time

Large Cross-axle Universal Shaft

Technical Parameters Of Product:

- Operating temperature: -20~+80℃

- Torque range: 1700kNm~5860kNm

- Swing diameter: 600~900mm

- Maximum deflection angle: ±15°

- Maintenance cycle: 360h/time

Hot Rolling Mandrel

- Internal Water Cooling (half-closed)

- Internal Water Cooling (open Type)

- Rod — Plunger Wedge-type Mandrel (reinforced)

- Rod — Plunger Wedge-type Mandrel

Cold Rolling Mandrel

- Pyramid Sleeve Mandrel

- Mandrel Of Pyramid Shaft Type

- Mandrel Of Wedge-open Type

- Mandrel Of Wedge-closed Type

Crowned Teeth Gear Coupling

- Conventional Crowned Teeth Gear Coupling

- Heavy-duty Crowned Teeth Gear Coupling

- Bar And Wire Rod Mill Crowned Teeth Gear Coupling

- Heavy-duty Crowned Teeth Gear Coupling Of Hot Tandem Finishing Rolling Stands

Technical Specification | |||||

Number of Tire Wire | Single or Double Ring | Wire Tightening Force | 9 kN | Wire Size | 6.3-8mm |

Bundle Size | 150-450mm; 200-650mm; 300-850mm; 450-1050mm | Value Voltage | 24V | Wire Material | Q195, Q235 |

Wire Guide Diameter | 700mm; 900mm; 1150mm; 1800mm | Motor Power | 11KW | Cycle Time | 7 s (single); 10 s (double) |

Hydraulic Pressure | 100bar | Pump Capacity | 100 1/min | ||

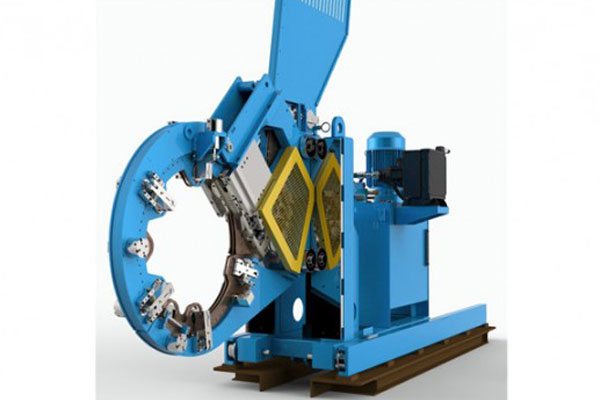

Bar Bundling Machine – TAIER

Information for Bar Bundling Machine – TAIER

Number of wraps

Single-wind single-knot

Tightening force

9 KN

Bar bundle size

Φ150-550 mm

Valve voltage

24 V

Inner diameter of wire track

Φ700-Φ900

Motor power

11 KW

Hydraulic system pressure

100 bar

Pump capacity

100 l/m

Tie wire size

6.3-8 mm

Tie wire materials

Steel wire Q195, Q235;

Binding cycle

Single winding for 7 s

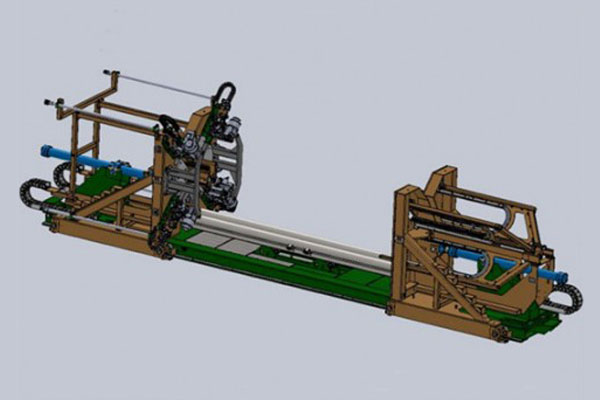

Compactor- TAIER

- Full-automatic Horizontal Wire Compactor

- Full-automatic Pp/pet Horizontal Strapping Compactor

- Full-automatic Steel Strip Horizontal Strapping Compactor

- Full-automatic Vertical Wire Compactor

Information for Compactor- TAIER

Full-automatic Steel Strip Horizontal Strapping Compactor

Equipment parameters:

Number of Bindings

4

Pressing force

60-400KN

Strap size

32mm

Effective opening

4700mm

Minimum opening

620mm

Strap thickness

0.8-1.0mm

Coil outer diameter

Φ1400mm

Coil inner diameter

Φ850mm

Strap material

Steel

Coil weight

2200kg

Maximum length of C-hook

4300mm

Binding cycle

32s

AMTEC HYDRACLAMP – CANADA

Amtec Hydraclamp – Canada

Authorized Distributor of Amtec-Hydraclamp in India,

We offer high-pressure clamping and tensioning solutions, including hydraulic nuts, pre-tensioning devices, block nuts, step nuts, and related accessories.

Amtec Hydraclamp™ Hydraulic Clamping Nuts are suitable for steel slitters, side trimmers, choppers and roll-forming lines, which all benefit from the exceptional safety, convenience, efficiency and highly controllable clamping.

Amtec Hydraulic Nuts safely and conveniently replace major mechanical nuts on all types of metal processing lines by eliminating sledge hammers and heavy wrenches, which cause much of the strain and physical injury to the set-up personnel. Bearing damage from hammering nuts is eliminated with Amtec Hydraclamp™ Hydraulic Clamping Nuts. Our piston activated hydraulic nuts provide positive, controlled clamping force applied with every installation to ensure reliably accurate tooling set-ups. Using hydraulic energy to create clamping force eliminates friction on threads, which is the prime cause of early thread wear.

F-Type

All Amtec F-Type Nuts are activated by grease to suit operating specifications. Amtec F-Type Nuts offer self-aligning, annular thrust rings, which create a high force lock to prevent unthreading once pressure is applied.

The extreme internal pressure pushes the thrust ring against the mating tooling and simultaneously forces the nut body to locate against the arbor or shaft threads. Therefore, all threads may be right hand rotation regardless of whether the arbor or shaft rotation is clockwise or counterclockwise. Amtec will custom manufacture all F-Type Nuts to any existing thread form, regardless of thread hand, provided the thread form conforms to international standards.

K-Type

All Amtec K-Type Nuts are actuated by pistons pressurizing a grease medium. Amtec K-Type Nuts offer self-aligning, annular thrust rings that create a high force to prevent unthreading once pressure is applied. The extreme internal pressure pushes thrust rings against the mating tooling and simultaneously forces the nut body to locate against the arbor or shaft threads. Therefore, all threads may be right hand rotation regardless of clockwise or counterclockwise shaft or arbor rotation.

Amtec will custom manufacture all K-Type Nuts to any existing thread form, regardless of thread hand, provided the thread form conforms to international standards. Amtec K-Type Nuts are manufactured from 4140 chromoly steel to withstand up to 700 bar (10,150 PSI) without stress or fatigue. All Amtec K-nuts are available with indicator pins that pop up when clamping pressure is met.

Straightener / Leveller Rolls

Classification | Material | Application |

WORK ROLL | GCr15(SUJ2) | Multi-Roll Straightening machine; Leveling Machine |

BACK UP ROLL | GCr15(SUJ2) |

Plate Straightener Rolls

Classification | Material | Specification |

WORK ROLL | 60CrMoV | L2500-L5200 L200-L1200 |

BUR/SR | 55NiCrMoV7 |

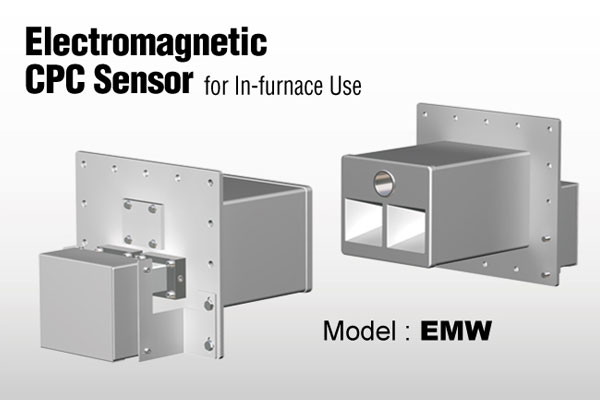

Nireco

Electromagnetic CPC Sensor

Detection operating principles and equipment configuration:-Electromagnetic waves from the antennae are reflected from the strip edges and the transmission time taken for the waves to return is used to measure the strip position. Even if dirt or other contaminants reduce the reception sensitivity, the transmission speed of the waves does not change, so the measurement is unaffected.

Edge Position Control Systems

The Photo head is the sensor in an EPC (Edge Position Control) system. It uses photoelectric principles to detect the edge of the strip (web). The sensor signal is transmitted to an amplifier. The amplified output signal is sent to a hydraulic jet pipe-type regulator, or a servo valve and the strip edge is controlled so that it remains in the determined position.

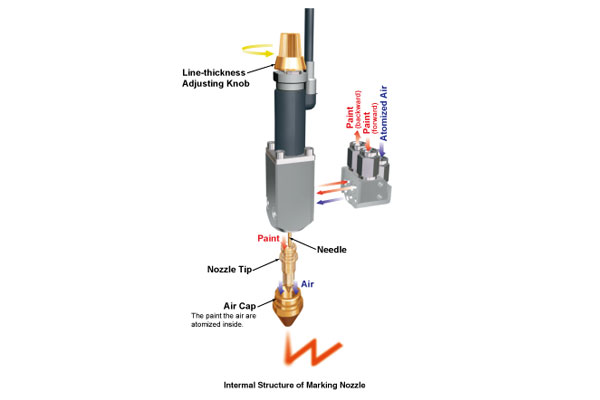

Automatic Marking Systems

Marking is performed in such a way that the nozzle is moved along the character shape in the X-Y stage and paint is ejected each time the nozzle is opened and closed as it moves a specified distance. Shortening the ejection timing produces continuous line characters; lengthening it produces dot characters.

- Robot Marker

- Lazer Marker

- Jet Marker

- Dot Marker

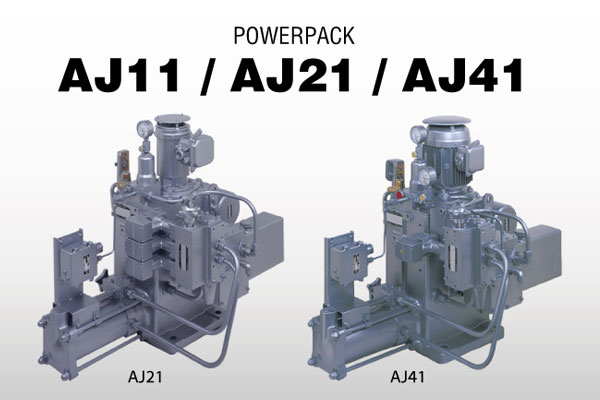

Powerpack

The Powerpack is an actuator that controls a load such as a valve.

As its output shaft performs rotary motions it is suitable for controlling a final control element of rotary type such as a butterfly valve.

BEARINGS

Categories

- Four-row Cylindrical Roller Bearing

- Double-row Cylindrical Roller Bearing

- Single-row Cylindrical Roller Bearing

- Bilateral Double-row Thrust Tapered Roller Bearing

- Spherical Roller Bearing

- Double-row Angular Contact Ball Bearing

- Four-point Contact Ball Bearing

- Deep Groove Ball Bearing

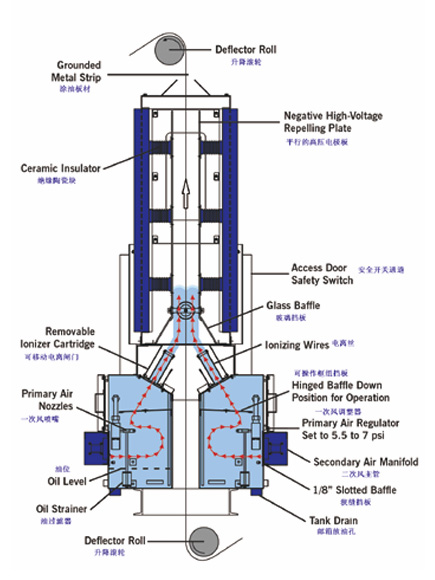

Electrostatic Oiler

Horizontal Electrostatic Oiler (H.E.S.O) was designed for uniform and precision oiling on the surface of continuous metal strip and sheet. State-of- the-art Nozzles-atomizer techniques can charge the mist during atomization and electrostatic absorption, which making it possible to coat uniform without blocking and skipping and lowest coating weight up to 20mg/m per side by strip travel horizontally.

Strip speed: 30-650mpm 2 2 20

Coating width (mm): 600, 1050, 1350, 1800, 2200 Coating tolerance: ±10%

Oil coating range (per side): LUB 20-300mg/m, RPS 300-2, 500mg/m, INF 20-2,500mg/m

Appearance: liquid

Viscosity: 40 cSt.@20 ℃

Conductivity: 750K-50M Ohm

Vertical Electrostatic Oiler(V.E.S.O) was designed to apply a very thin lubricant coating on the surfaces of electrolytic tinning, tin free steel, or aluminum coating coil as it passes through the oiler.

Coating Weight Range: 1 to 12.5 mg/sqm per side Strip Speed Range:30 to 650 MPM

Coating Width (mm): 750, 1100,1220,1650,2200

Diaphragm Compressor

Capacity : 2 Nm3/hr to 300 Nm3/hr

Suction pressure starting from 0.5 bar & Discharge pressure up to 1400 bar

Large & small hydrogen compressors for any application

Our compressors feature:

- Leak Free Design

- Contamination Free Compression

- Corrosion Resistance

- High Compression Ratios

- High Reliability

- Safety

- Automatic Leak Detection

Gas best suited for our compressors

Our Diaphragm Compressors are ideal for a variety of gases, including:

- Toxic gases such as Carbon Monoxide

- Explosive gases such as Hydrogen, Ethylene, and Methane

- Reactive gases such as Oxygen and Fluorine

- Expensive gases such as Neon, Krypton, and Xenon

- Radioactive gases such as Tritium

- High Purity gases such as Nitrogen, Helium, Argon, etc

Screw Conveyors

To design, manufacture and supply complete screw conveyor systems

Tailor-made screw conveyors: screw conveyor systems are tailor-made for many types of product processing across a wide variety of markets.

Advantage:

- Over 30 year’s experience of designing and manufacturing screw conveyors

- Fully conversant with all of the standards required

- Complete in-house production from design to delivery

- High quality, accurate in-house screw flight pressing and production

Other Products

- Multistage Blowers

- GIGL Inductor Zinc Pot & Galvanised Equipment

- Liquid filling Machine

- PP, Ball Valves, PVDF Pumps & Valves

- Agitator

Ready to Transform Your Operations?

Let us help you achieve efficiency and excellence.